02 October 2024

How Often Should a Coffee Machine be Serviced?

Jack Merriman

Digital Marketing Manager

When it comes to coffee machine maintenance, prevention is always better than repairing. When your business relies on your commercial coffee machine(s) being operational in order to function, the last thing you need is downtime while you wait for your machine to be fixed.

Coffee machines aren’t complicated (for the most part) but they do require regular maintenance in order to remain in the best working condition – and that includes getting your commercial machine serviced regularly to head off any potential issues.

This blog provides tips on how to maintain your coffee machine, the benefits of regularly servicing a machine (and what can happen if you don’t) and how often each type of machine needs servicing. We’ll cover:

- How to maintain your coffee machine

- Common maintenance problems

- When to service your machine

- Why you should stay on top of your coffee machine servicing

- What to look for in a servicing partner?

Maintaining a Commercial Espresso Machine

Compared to other types of commercial coffee machines, traditional barista-operated espresso machines are relatively simple and easy to maintain. Alongside a small number of bells and whistles, an espresso machine’s job is to heat water up to temperature and push it through a finely ground puck of coffee – there’s not a huge amount that can go wrong in this process.

However, just like owning a reliable car, issues can still arise now and then – and your commercial espresso machine will require a small level of care and maintenance in order to function properly.

Common Maintenance Problems with Commercial Espresso Machines

The most common maintenance issues surrounding commercial espresso machines stem from the buildup of scale inside the machine due to poor water quality.

Limescale Buildup

Espresso machines heat their water inside pressurised boilers, and this environment can lead to mineral deposits being left inside particular areas of the machine. This is a common problem in hard water areas, where large amounts of calcium and other minerals in the water can build up inside your espresso machine. This is most commonly referred to as limescale.

Limescale build up in your espresso machine can lead to blocked pipes and valves, reducing water flow and steam pressure inside your machine. This prevents you from being able to brew at the correct temperature and pressure, leading to weak, sour tasting coffee, and prevents you from properly steaming your milk. Over time, water will stop flowing through your machine entirely.

Breakdown of Parts

Additional, less serious issues can arise with the wearing down of common affordable parts that are built to be replaced, such as silicon seals and gaskets that keeps the machine water tight and secure during brewing.

When these parts wear down, water might start leaking out from the group handle when brewing, you may not be able to achieve optimal brew pressures making your espresso taste weak, and steam power may seem to be reduced, making it difficult to heat and texture your milk.

How to Maintain a Commercial Espresso Machine

Water Treatment

In order to significantly reduce the risk of limescale buildup, every coffee outlet should have a properly treated water system. Making sure that the water flowing through your espresso machine is of the right chemical makeup will significantly reduce limescale buildup, and help your coffee taste even better by using freshly filtered water.

Before installing an espresso machine, your coffee engineer should test your water for hardness level and chemical makeup to prescribe the right type of filter for your needs. Learn more about water filtration options for your café -> A Cafés Guide to BRITA Commercial Water Filters.

Preventative Maintenance

In order to combat the natural wearing down of the cheap, replaceable parts of your espresso machine, preventative maintenance should be carried out regularly. This involves replacing the seals, gaskets, shower screens and baskets of your machine before they break, eliminating the risk of breakdowns, along with descaling the machine to remove any build up of limescale.

Daily and Weekly Cleaning

Commercial espresso machines are relatively bullet proof when looked after properly. They don’t really have any internal moving parts. Making sure to clean your espresso machine on a daily basis with backflush chemicals and simply brushing down and removing any built up coffee grounds or oils goes a long way in ensuring a long lifespan for your machine.

Learn more about how to keep an espresso machine clean here -> How to Keep an Espresso Machine Clean.

When Should a Commercial Espresso Machine be Serviced?

Commercial espresso machines should be serviced every six months with a standard preventative maintenance visit from your coffee machine engineer.

Along with swapping out the seals, gaskets, shower screens and baskets, the engineer will provide you with a new water filter to keep the coffee tasting great and limescale buildup to a minimum.

Every other visit, or every 12 months, your espresso machine legally requires a PSSR inspection to ensure the steam boiler is functioning properly to reduce the risk of harm to the user.

A PSSR inspection prevents unexpected breakdowns and malfunctions of your steam boiler to protect the user and reduce any downtime for your machine. You can learn more about PSSR inspections here.

Maintaining a Bean-to-cup Machine

Compared to traditional espresso machines, bean-to-cup machines are far more complicated pieces of machinery.

Not only do they have to brew coffee under high temperatures and pressures, they need to grind the beans into a fine powder, prepare the puck of coffee for the brew, move and dispose of the used coffee grounds, and automatically steam and dispense hot foamed milk.

This process requires a bunch of moving parts, which can occasionally fail and need replacing, especially if your bean-to-cup machine is not being properly cared for.

Common Maintenance Issues for Bean-to-Cup Machines

The main issues that arise with bean-to-cup machines stem from a lack of regular maintenance and cleanliness on the part of the user, though some parts of the machine will naturally wear down over time.

Milk Buildup and Spoilage

Milk is a perishable product that can spoil after a few days. A common issue with bean-to-cup machines, especially in low-volume settings, is for the milk to spoil and buildup inside the machine.

This problem can be exacerbated when the bean-to-cup machine is not regularly cleaned, as stagnant milk sitting within the inner workings of the machine is likely to spoil and build up overnight.

Grinders Failing

Bean to cup machines include at least one, often two, coffee grinders that turn your delicious coffee beans into a fine powder. The cutting teeth on the burrs dull over time, causing whole beans to jam inside the grinder mechanism, preventing you from brewing coffee.

Limescale Buildup

Like in commercial espresso machines, hard water can lead to a build up of limescale inside the boiler of the bean-to-cup machine, preventing coffee from being brewed. Many bean-to-cup machines now come with semi-automated descaling programmes to remove limescale to negate this issue.

How to Maintain a Commercial Bean-to-Cup Machine

Taking proper care of your bean-to-cup machine is the best way to reduce the number of breakdowns, saving you money from downtime and engineer callouts.

Daily Cleaning

To avoid issues with your commercial bean-to-cup machine, a large emphasis must be placed on its cleanliness. Failing to clean your machine regularly leads to a build up of milk, coffee grounds, beans and oils within the machine, eventually leading to breakdowns, downtime and engineer callouts.

Thankfully, bean-to-cup machine manufacturers recognise this need for cleanliness, and build semi-automated cleaning processes into their machines. At least once daily, make sure your teams are following the recommended cleaning programmes on the screen of your machine using the correct chemicals provided by your supplier.

Regular Descaling

Just like with the daily cleaning reminders, your bean-to-cup machine prompts you to descale your bean-to-cup machine every few months depending on usage.

Depending on the machine make and model, the descale process could take a few hours, but all processes will be shown as clear instructions on your machine’s screen. Also keep in mind that a properly treated water source will reduce the risk of limescale buildup, reducing the need to descale the machine.

Preventative Maintenance

As some parts of your bean-to-cup machine are constantly working under harsh conditions, they are bound to fail. Maintaining your bean-to-cup machine properly avoids unexpected breakdowns by proactively replacing parts that often wear away.

Every six months, we recommend proactively swapping out the gaskets, burrs and seals of your bean-to-cup machine before they break to prevent any unexpected issues.

When to Service a Commercial Bean-to-Cup Machine

Your bean-to-cup coffee machine should be serviced by a qualified coffee machine engineer every six months. This helps to maintain optimal performance of your machine for great tasting coffee and to reduce the risk of unexpected breakdowns.

A proactive service varies depending on the visit and type of machine, but typically includes installing a new water filter, conducting a PSSR inspection on any pressurised boilers, replacing any parts susceptible to breakdowns, conducting a descale if required and replacing the grinder burrs.

Of course, if your bean-to-cup machine is already showing signs of breaking down, such as a lack of coffee flowing, odd noises or warning alarms, you’ll want to have it serviced immediately.

Having a team of engineers on hand that you can call when things go wrong can be invaluable. Learn more about our in-house engineer team here -> Service and Repairs

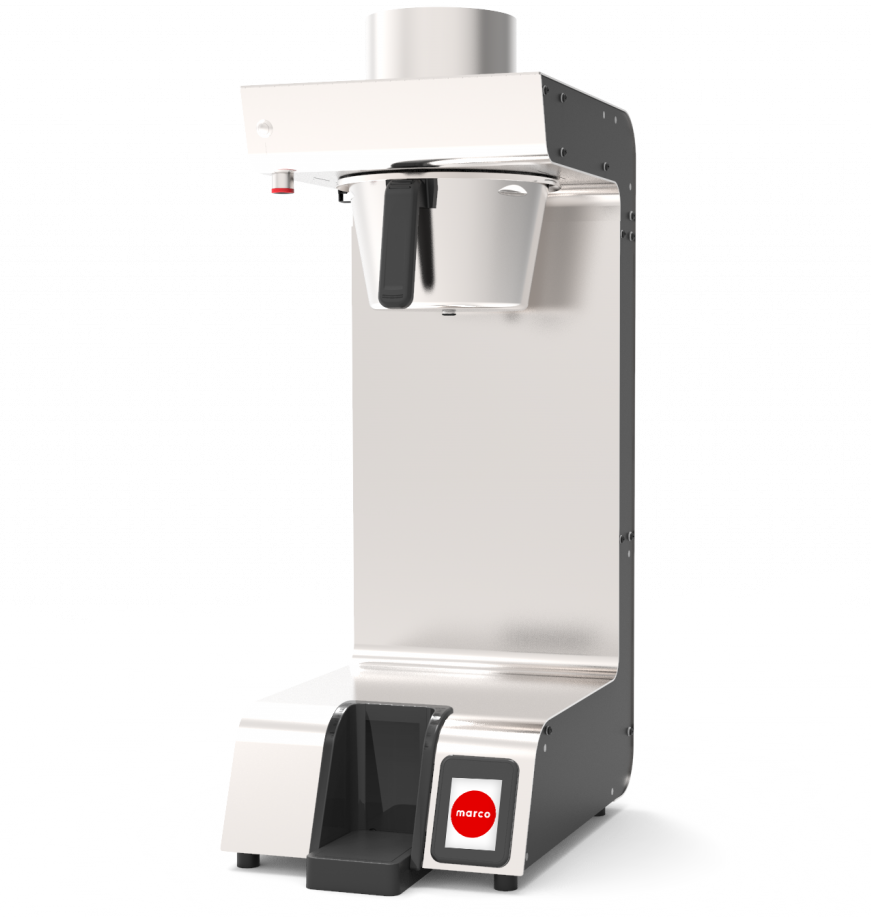

Maintaining a Commercial Filter Coffee Machine

Taking care of your filter coffee machine is a relatively simple process as, by design, they are essentially hot water boilers connected to shower screens with a few extra features.

Properly maintaining your filter coffee machine therefore largely comes down to keeping the machine clean, along with making sure any servers are cleaned and rinsed after use.

To make sure your brewer is clean of any coffee oils and buildup, make sure to rinse and wash the coffee server with dish soap after every batch of coffee, and clean the external parts of the machine every day. This includes the shower screen, the filter basket, and any other parts that could come into contact with the brew process.

You could also run a short ‘empty’ brew cycle with no coffee in the basket at the end of every day to ensure you have rinsed the machine of any spent coffee. Having your water properly filtered according to your water quality also ensures that scale buildup is kept to a minimum, though we would still recommend descaling any filter coffee machine every six to 12 months.

When Should You Service a Filter Coffee Machine?

Because filter coffee machines are simple machines, with commercial models being built to withstand high workloads, they rarely need servicing.

As long as daily cleaning is carried out, and the water treatment is well-suited to your water source and being regularly replaced every six months, a filter coffee machine does not typically require proactive maintenance and servicing.

We would suggest commercial filter coffee machines only need servicing when they start to show signs of an imminent breakdown. This can include a slow flow of water, which indicates a partial blockage, a machine struggling to get up to temperature, or unexplained bad tasting coffee.

Why you Should Stay on Top of your Coffee Machine Servicing

On average, a typical commercial coffee machine will break down between 1 and 4 times per year. The number of times your machine breaks down is directly linked to how often it is being serviced and how well it is being looked after by your team.

Regular Servicing Prevents Breakdowns

General wear and tear is a factor of life for any commercial coffee machine, and some parts will wear away over time. Making sure that these parts are replaced proactively before they break ensures that you won’t be caught out by unexpected breakdowns and machine down time.

Unexpected Breakdowns Affects your Revenue

If your coffee machine breaks down, it can take time to find an engineer to come and resolve the issue. In this down time, you’ll have to turn customers away and lose out on coffee sales until

Routinely servicing your machine reduces the occurrence of unexpected breakdowns significantly, saving you money on lost revenue and ensuring you don’t upset your customers. When issues do occur, having a service plan in place can help get an engineer to you faster.

Repairs Cost Money

Failing to keep on top of your regular servicing and maintenance will lead to unplanned breakdowns, and the repairs can be a significant cost that you need to consider. Not only will you have to pay for the cost of replacement parts, it will also cost you to get an engineer to your site in the first place and for their time spent working on the machine.

Having a service plan in place that includes replacement parts free of charge and covers you for the time spent on site can significantly reduce the costs of repairs and regular servicing.

Servicing Plans Provide Peace of Mind

Investing in a service plan with a team of coffee engineers is the most cost efficient and effective way of ensuring your machines maintenance and regular servicing is kept on top of. If you have a Service Level Agreement with our team of engineers, your machine will be proactively serviced every 6 months by a qualified engineer and you will receive regular reports as to how well your team is taking care of their equipment.

In the rare occurrence when your machine does break down, your service plan ensures that you have someone to call to fix the issue with free replacement parts, guaranteed response times, free labour on site and weekend coverage.

What to Look For in a Servicing Partner

Enlisting the help of a coffee machine servicing team is an effective way of looking after your machine for the long term with regular maintenance and repairs. Here are just a few things to look for when deciding which servicing partner to work with.

Proven record of looking after machines

Make sure any service provider has a proven track record of looking after and properly servicing machines. This could involve asking your connections for recommended providers, taking a look at their case studies and written reviews online, and even trialling their services for a short time at one of your sites before a full roll-out.

Expertise on your equipment

Have a browse of their website to see what brands and models of coffee machines they are able to service to see if they can support your equipment. Some machines may require dedicated training to service along with access to specific parts that not every service provider will be able to supply.

No Hidden Costs

Take a look at all the costs associated with your repairs and service plans, making sure to ask about any hidden costs. One place you may get caught out is the cost of additional labour time on-site and the cost of replacement parts, both of which are included in our service plans.

Fast Response Time

Ask about their response times to make sure you have clarity of how fast they can get your machine up and running. A respectable response time should fall within one to three business days of the issue first being reported, potentially faster if they have the parts you need in stock, local engineers and have a clear picture of the problem before visiting.

Offers Weekend Cover

Hospitality, retail and leisure businesses serving coffee seven days a week, definitely need to make sure their servicing partner includes weekend (and bank holiday) callouts as part of their service. It’s also worth checking if there are additional costs for these hours.

High % First Time Fix Rate

A first time fix rate is just what you’d think, what proportion of engineer callouts result in your machine being fixed, without needing a follow up visit.

Occasionally a breakdown requires more than one visit if there are unexpected issues or rare parts that need sourcing.

A 96% first time fix rate is a great benchmark to look for when deciding on a coffee machine servicing partner, indicating that they will be able to fix your machine on the first visit 24 times out of 25.

Protect your Machine from Downtime with Bridge Coffee Roasters

Engaging the services of a coffee equipment service partner is the best way of ensuring your machines are well-looked after and proactively maintained to reduce frustration and lost revenue caused by unexpected breakdowns.

With a first time fix rate of 98.16%, no hidden costs, weekend and bank holiday coverage, and fast response times of 24 working hours, our team of engineers are ready to provide peace of mind with our Service Level Agreements.